In the broadest sense, a composite material is one that consists of two or more distinct materials—which retain their individual properties even when the final material is formed! In fact, we’ve all encountered various composite materials in our everyday lives.

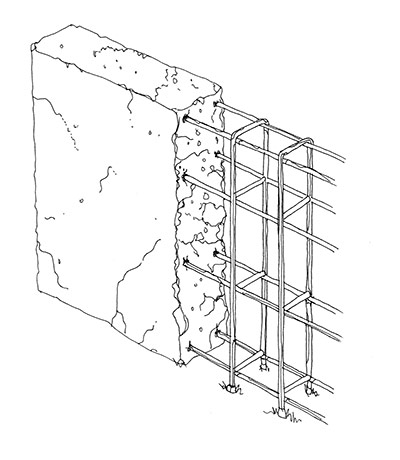

Aggregate Concrete. (Source)

Take concrete, for example. Have you ever seen concrete being made for construction? It comprises cement (which binds everything together) and many other materials, including crushed stones. The properties of concrete are a combination of the properties of everything that went into it. Moreover, if concrete in its finished form is seen under the microscope, one finds that the components are essentially “mixed in”, and don’t interact chemically with each other in any way.

(This is, in contrast, to things such as alloys. Alloys, for example, are also made of multiple components—mostly metals, sometimes nonmetals such as carbon—but the final product has vastly different properties than the constituent materials. Also, the components themselves interact with each other at the smallest scale, and are not simply “mixed together”.)

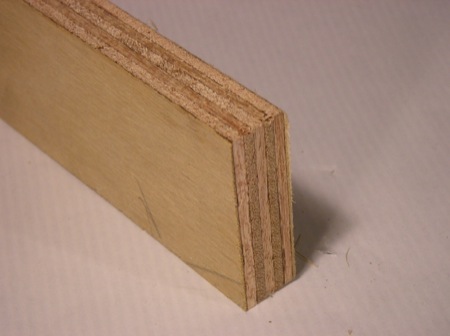

Plywood is another example of a common composite material. In this case, you don’t even need a microscope: the individual layers making up the plywood are evident quite easily! In fact, while we’re on plywood, let’s remember the word ply—it refers to each layer of wood that makes up the plywood (yes, that’s how it gets its name). We’ll use the word ply plenty times later on.

Plywood. (Source)

Okay, so that’s what composites are in the broadest sense.

But in an engineering and research perspective, a “composite” is something more specific. To wit, a composite material is an engineered material, in which one or more heterogenous components are used as reinforcement in a matrix of homogeneous material. If the material used as a matrix is a metal, it’s called a Metal Matrix Composite (MMC).

Okay, so let’s break that last paragraph up a little bit. First, the “matrix of homogeneous material”. This refers to any material that’s uniform (like cloth, gauze), which serves as the base for your composite, and between layers of which—or even into which—you can embed other things if you wanted to. (In concrete, the cement can be thought of as the matrix, into which you can add other things—including steel rods to create reinforced concrete!)

Reinforced Concrete. (Source)

As I already said, if the matrix material is a metal, the composite is called an MMC. But a variety of other materials are also used as the matrix material—different kinds of polymers, usually. The most popular one that I’ve come across is epoxy resin, but other than that, vinylester or polyesters are also used.

The reinforcing material in the composite is usually either a fiber (more common) or a particulate material (less common). Since fiber-reinforced polymers are more common—and what I mostly work with—let’s talk about fibers a little bit.

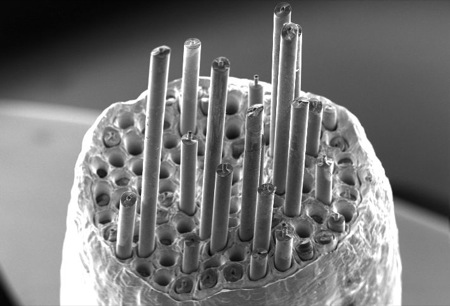

Fracture surface of a SiC fibre-reinforced Cu metal matrix composite. (Source)

Fibers are a source of strength in composites, and a number of different kinds of fibers are used. Most common are carbon fibers, glass fibers, or even boron fibers. The question, of course, is—if the fibers add strength, why not build the entire material out of the same material as the fiber? Well, due to the way materials are manufactured, larger the size of the building block (i.e. the smallest unit used over and over again), lower is the overall strength. Hence, for example carbon in fiber form is much, much stronger than carbon in, say, sheet form (interested readers should look up “carbon fiber whiskers”–I could not find appropriate web pages to link to). This is why fibers are used for strength, and other materials (the matrix) are used to hold everything together around the fiber. (One can think of Metal Matrix Composites as special cases where even the matrix needs to be strong in its own right.)

Thus, to summarize, a composite material usually comprises a homogeneous matrix material, in which certain fibers are embedded to add strength and other advantages to the material. In some cases the matrix can be a metal, in which case the overall material is even stronger.